18 Years Factory Electrical Aluminum Enclosure - Good Quality Aluminum Stamping Parts – R&H

18 Years Factory Electrical Aluminum Enclosure - Good Quality Aluminum Stamping Parts – R&H Detail:

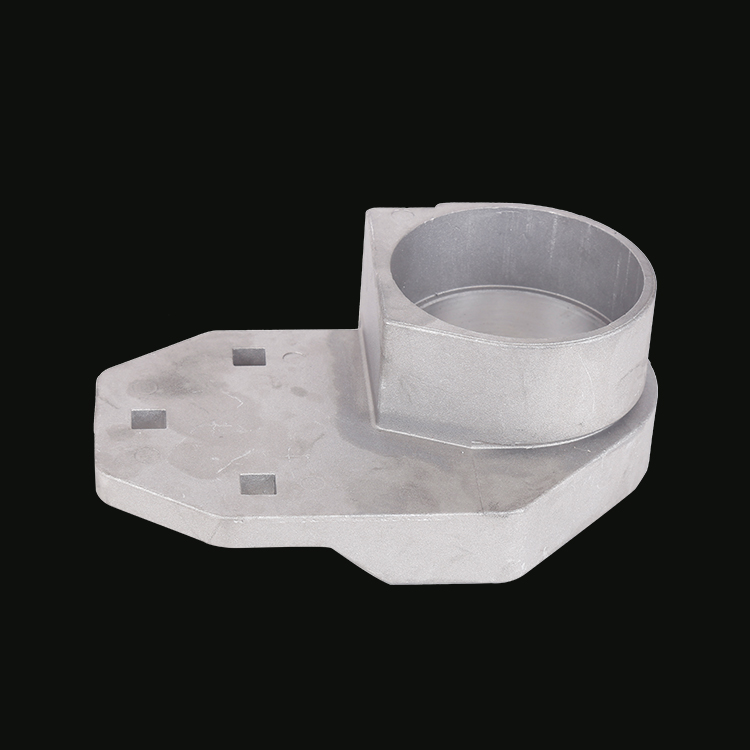

PRODUCT SPECIFICATION

| HARDNESS | 58-62HRC |

| APPLICATION | Machinery |

| SURFACE TREATMENT | Polishing |

| COLOUR | Aluminum natural color |

| MATERIAL | Aluminum |

| TECHNOLOGY | Cast Aluminum |

| FEATURE | Stable Performance : low Voice |

TRANSFER PROGRESSIVE DIE METHOD

In this method, uniquely designed line dies are assembled together in a predetermined structure in a single press. Unlike with conventional line dies, the traveling rails assist the movements of metal parts. The rails are mounted in the press boundaries. During a press cycle, each rail moves inward to grab the metal part with specialized finger-like structure, which transfers metal parts to the next die.

1.With this method, large parts are handled rapidly

2.Based on the requirement, stamped parts can be rotated, if necessary, during the transfer process

3.Can be programmed to accommodate a large variety of parts for different press speeds and stroke lengths

ADVANTAGES OF ALUMINUM STAMPING PARTS

1.Cost-Effective

Metal stamping services are cost-effective because the process is able to produce material-intensive parts at production rates that are much greater than what is possible using other traditional methods. Because the process is so fast and accurate, its well-suited for higher-volumes; as the production level increases, the labor costs and the per piece set-up drop.

Many parts made through other metal forming processes, such as casting, die casting, forging, machining or fabricating, could just as easily be designed for stamping. Metal stamping dies have a lower tooling cost than many others, such as molds, forging and casting dies and expendable cutting tools.

2.Precise

Both standard and complex custom metal stamp parts are stamped with precision (including precision tolerances) and high repeatability. Precision stamping offers benefits such as material flow, drawing, tight tolerances, and repeatability that are not possible with other metal fabrication techniques. These benefits become more evident in heavier parts.

3.High Quality

Metal stamping brings a level of quality, accuracy, function, wear life and appearance to parts that they would not have otherwise. Also, metal stamping allows parts to be made of tougher and harder material than other processes allow, including such materials as stainless steel, nickel, cold rolled steel, aluminum, brass, bronze and galvanized steel.

PACKAGING & PAYMENT TERMS & SHIPPING

1.Packaging Detail:

a.clear bags inner packing, cartons outer packing, then pallet.

b.as per customer’s demand for hardware stamping parts.

2.Payment:

T/T,30% deposits advance; 70% balance before delivery.

3.Shipping :

1.FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2.By Air or by Sea for batch goods, for FCL;Airport/ Port receiving;

3.Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

WHY CHOOSE US

FAQ

I know you have many questions about our R&H. Never mind, I believe you will find the satisfied answer here. If there is no such questions you want to ask, please don’t hesitate to contact us by email or online.

1.What about the delivery time?

Normal mold time: 10-12 days Machined parts: 3-5 days Batch: 10-15 days depend on quantit.

2.How about your after-service?

Quality issue,If it is our fault,100% remake or as customer’s requirement,if not our fault,try our best to give some discount to remake.

FACTORY SHOW

Product detail pictures:

Related Product Guide:

We always continually offer you by far the most conscientious customer service, and the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for 18 Years Factory Electrical Aluminum Enclosure - Good Quality Aluminum Stamping Parts – R&H , The product will supply to all over the world, such as: Amsterdam, South Korea, Jamaica, We will supply much better products with diversified designs and professional services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.