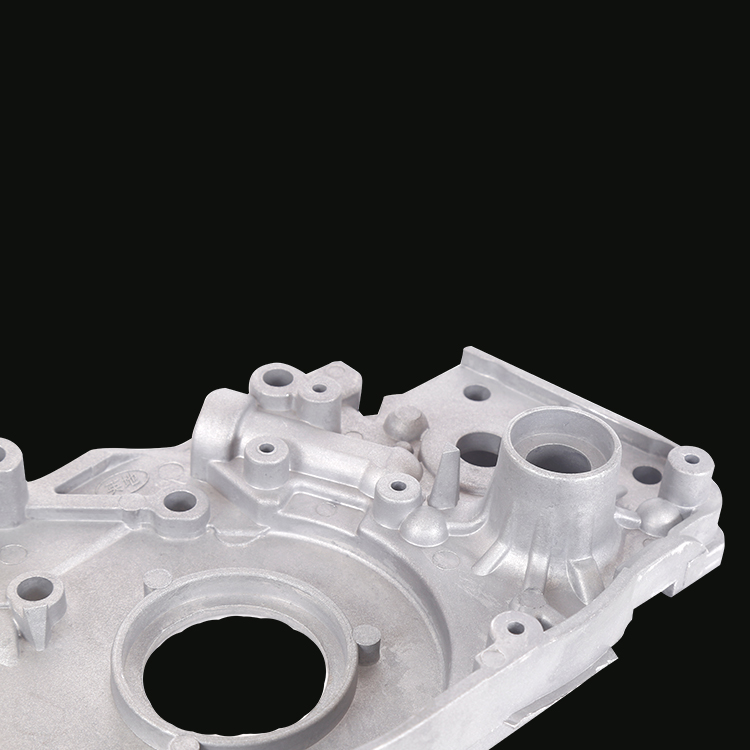

Factory made hot-sale Low Pressure Die Casting Alloy Wheels - Customized Die cast aluminum auto parts in stock – R&H

Factory made hot-sale Low Pressure Die Casting Alloy Wheels - Customized Die cast aluminum auto parts in stock – R&H Detail:

PRODUCT SPECIFICATION

| DIAMETER | 120mm-400mm |

| THICKNESS | 2.5mm |

| SURFACE TREATMENT | Polishing |

| COLOUR | Aluminum natural color |

| MATERIAL | Aluminum ADC12 |

| TECHNOLOGY | Die Cast Aluminum |

| APPLICATION | Cars / Auto parts |

ADVANTAGES OF OUR CASTING PROCESS

1. Less Machining

Machining is a costly operation. Our goal as manufacturing engineers is to minimize secondary machining and its costs by providing close dimensional control, a smooth finish, and total repeatability. Surfaces can be cast truly flat, sometimes even free from any draft or taper by suitable mold design. Time after time, switching from other processes to Permanent Mold has cut our customers’ machining costs dramatically.

2. Low Cost

Perhaps the greatest advantage of our castings is our competitiveness. Reducing machining gives our customers a low unit cost while tooling investments are minimized by our skilled engineering and mold shops. They use their years of experience and extensive knowledge to produce innovative mold designs that result in tooling costs often comparable to sand casting.

PACKAGING & PAYMENT TERMS & SHIPPING

1.Packaging Detail:

a.clear bags inner packing, cartons outer packing, then pallet.

b.as per customer’s demand for hardware stamping parts.

2.Payment:

T/T,30% deposits advance; 70% balance before delivery.

3.Shipping :

1.FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2.By Air or by Sea for batch goods, for FCL;Airport/ Port receiving;

3.Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

WHY CHOOSE US

.POWDER COATING

Color & Texture

Color selection is virtually unlimited with high and low gloss, metallic, and clear finishes available. Colors stay bright and vibrant longer, even after years in the sun and harsh conditions. Texture selections range from smooth surfaces to a wrinkled finish designed for hiding surface imperfections. A wide array of specialty effects are easily accomplished which would be impossible to achieve with other coating processes.

FACTORY SHOW

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for Factory made hot-sale Low Pressure Die Casting Alloy Wheels - Customized Die cast aluminum auto parts in stock – R&H , The product will supply to all over the world, such as: Zurich, Israel, Holland, Our factory insists on the principle of Quality First, Sustainable Development, and takes Honest Business, Mutual Benefits as our developable goal. All members sincerely thanks for all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.Thanks.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!