Top Suppliers Metal Stamping Machine Parts - Aluminum die casting auto parts – R&H

Top Suppliers Metal Stamping Machine Parts - Aluminum die casting auto parts – R&H Detail:

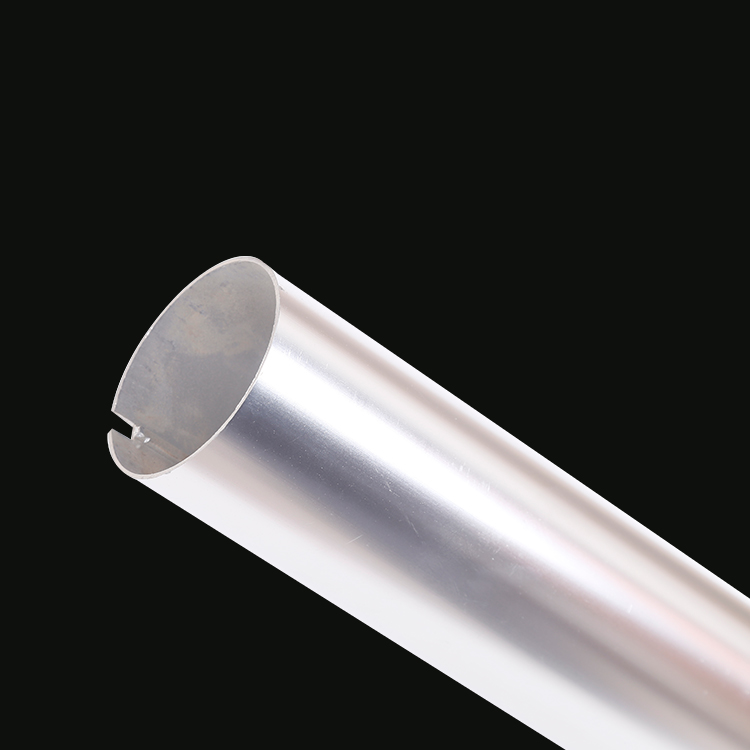

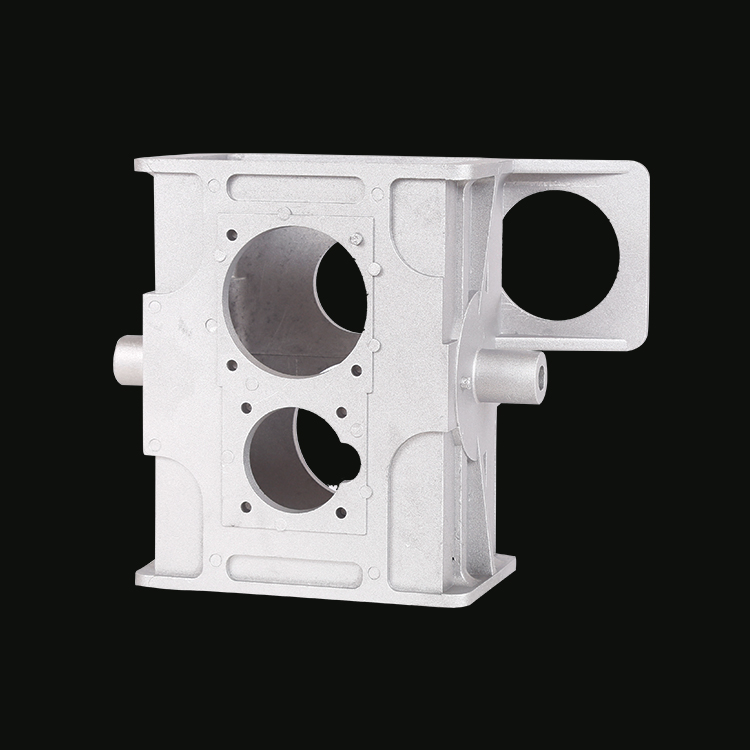

PRODUCT SPECIFICATION

| DIAMETER | 125mm*200mm*360mm |

| THICKNESS | 3.5mm |

| SURFACE TREATMENT | Sand Blasting / Polishing |

| COLOUR | Aluminum natural color / OEM color |

| MATERIAL | Aluminum A380 |

| TECHNOLOGY | Aluminum die casting |

| APPLICATION | Connectors / Membrane keypads |

ADVANTAGES OF OUR CASTING PROCESS

1. Flexible Quantities

flexible

Another way Gupta Permold can meet your most demanding requirements is with flexible production quantities. The activity of some of the castings pictured above range from 250 pcs/yr to upwards of 100,000 pcs/yr. Both are possible due to our innovative mold designs which skillfully balance tooling costs and unit costs.

2. High Strength

In our Permanent Mold Process, molten aluminum is poured into a metal mold that rapidly chills the aluminum. This causes the metal to solidify into a very fine-grain texture free of porosity and trapped gas. In turn, this gives our castings superior metallurgical properties, a high degree of pressure tightness, and a strength advantage greater than 15% over sand castings, alloy to alloy.

PACKAGING & PAYMENT TERMS & SHIPPING

1.Packaging Detail:

a.clear bags inner packing, cartons outer packing, then pallet.

b.as per customer’s demand for hardware stamping parts.

2.Payment:

T/T,30% deposits advance; 70% balance before delivery.

3.Shipping :

1.FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2.By Air or by Sea for batch goods, for FCL;Airport/ Port receiving;

3.Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

WHY CHOOSE US

POWDER COATING

Background

Powder coating provides the most economical, long-lasting, and durable quality finishes available. Powder coated surfaces are more resistant to chipping, scratching, fading, and wearing than most other commercial finishes.

FACTORY SHOW

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of Top Suppliers Metal Stamping Machine Parts - Aluminum die casting auto parts – R&H , The product will supply to all over the world, such as: Provence, Niger, United Arab Emirates, Faced with the vitality of the global wave of economic integration, we are confident with our high-quality products and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!